Global business drivers related to computing, data processing, and social media continue to push the semiconductor manufacturing requirements to levels never before achieved. Individual manufacturers as well as technical consortia around the world are working to develop manufacturing systems with the precision levels necessary to produce the next generation chip.

In mapping the technology gaps necessary to achieve next generation performance, there are a variety of areas that represent challenges. Specific to motion control, the precision required to yield position stability at the sub 1 nanometer level has been identified as a major requirement. It is expected that EBeam imaging resolution will require positioning stability of less than 1nm for extended time periods.

Now motion control manufactures must come to respect one nanometer.

Travel to 500mm

Speed to 100mm/sec

Position Resolution to 0.1nm

Position stability of 1nm over 10 hours

How else can we help?

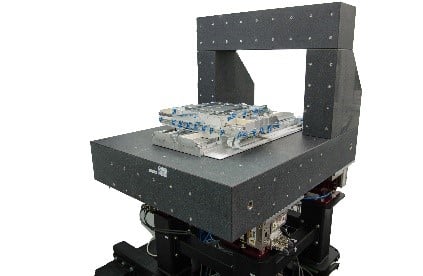

Achieving the required level of performance must come from a methodical and system design perspective. It is not simply a function of increasing position feedback resolution, but rather considering the impact of every component, such as materials, bearings and motors. This also requires thorough analysis for thermal and vibration impact, taking into account the operating environment.

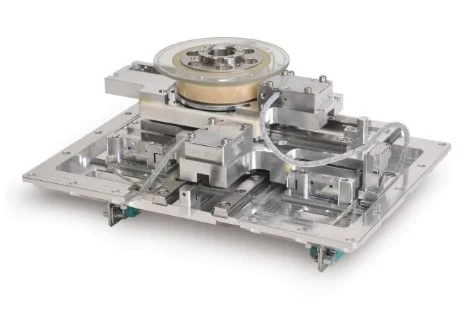

Utilizing a system design approach, considering all component and environmental factors, Nanomotion has developed and deployed multiple modes of operation within its piezo motor & control to facilitate meeting next generation requirements.

In a single motor or axis, Nanomotion is providing long travel with velocity to 500mm/sec and sub-nanometer positioning. In addition to these modes, the ability to compensate for thermal drift and to do active vibration suppression, allows one single drive technology to close the technology gap from a motion perspective.

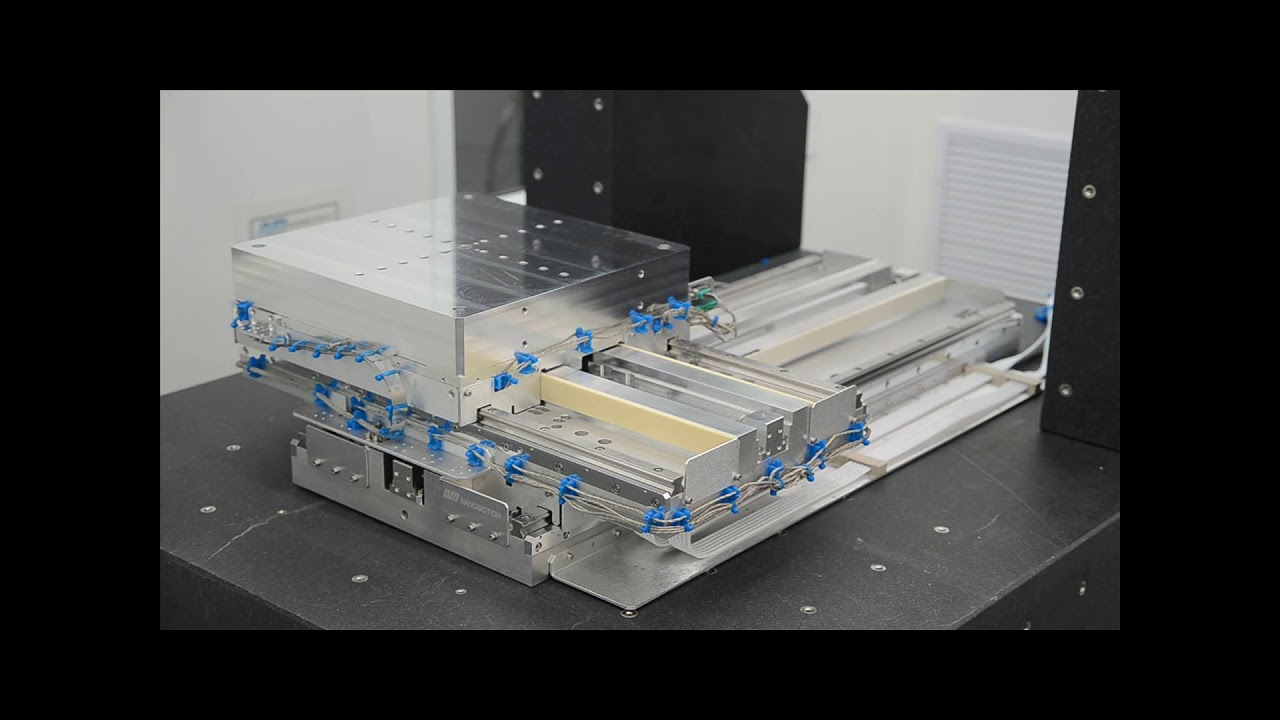

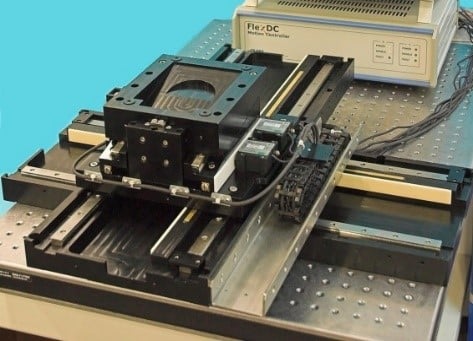

Nanomotion’s PS Stage incorporates the new SE motor, which provides significantly higher stiffness and efficiency, has demonstrated sub 1nm performance for meeting these application requirements. The stage can support encoder resolution below 0.1nm (down to 32pm) and provides the structural integrity to meet stable performance.

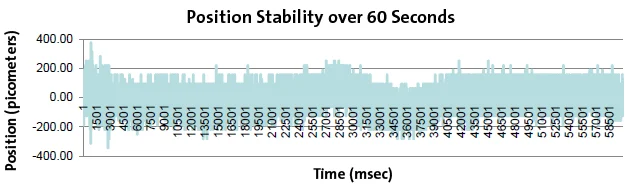

Shown below – Position stability over 60 seconds, within ±200pm

Nanomotion has demonstrated, in a variety of system designs, the ability to achieve 1nm positioning. The ability to utilize a single piezo motor to drive an axis over long travel distances coupled with the ability to stop and manipulate within the nanometer realm and 1nm stability for hours, is the enabling technology for next generation of precision machines.

| For a complete understanding of system designs and performance levels, please contact Nanomotion at nano@nanomotion.com or +1 (631)585-3000, or visit www.nanomotion.com. |

About

Utilizing proprietary technology, Nanomotion designs and manufactures complete motion solutions from start to finish.

Motion Solutions By Industry

Nanomotion’s team consists of engineering resources with more than 100 man years of precision motion control experience. The true measure of reliability is to evaluate our motor performance on a system designed and manufactured by Nanomotion.

For more information, please contact Nanomotion by email, call +1 (631) 585-3000