Industry Application

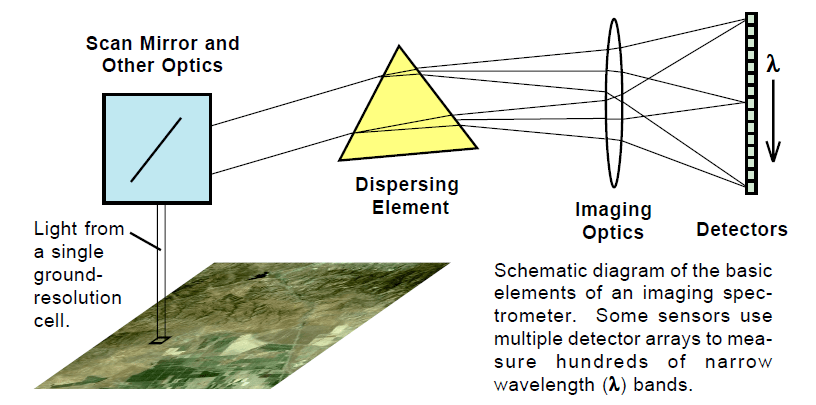

Hyperspectral Imaging leverages the convergence of two technologies; spectroscopy and the remote imaging of the Earth & planetary surfaces, to process data across the electromagnetic spectrum. The core objective of this process is to obtain the spectrum for each pixel in the image of a scene, ultimately for identifying objects, materials or processes. Hyperspectral imaging divides the spectrum into many bands, beyond the three bands visible to the human eye (red, green, blue) and provides the ability to analyze agriculture, biomedical imaging, threat detection of substances and gasses, surveillance, and many other applications.

Hyperspectral imaging utilizes four basic techniques for acquiring three-dimensional datasets. Spacial scanning, Spectral scanning, Non-scanning (snapshot) and Spatiospectrall scanning.

Spatiospectral Scanning uses multiple 2D sensors, each representing wavelength-coded spatial map of the scene. Advanced scanning can be achieved by moving the system relative to the scene, combining advantages of spatial and spectral scanning.

Today, the success of Hyperspectral imaging relies on a variety of motion technologies to operate with high performance in a small operating envelope. The scan mirror often needs to move at a very controlled and uniform velocity to collect data over a wide area. Additionally, focus mechanisms and filter changers are often used in conjunction with the imaging optics. However, one of the latest advances in the use of hyperspectral imaging is the ability to utilize a Tunable Filter Mechanism that can provide ultra-high resolution, high speed scanning, operating in a Dewer and at cryogenic temperatures.

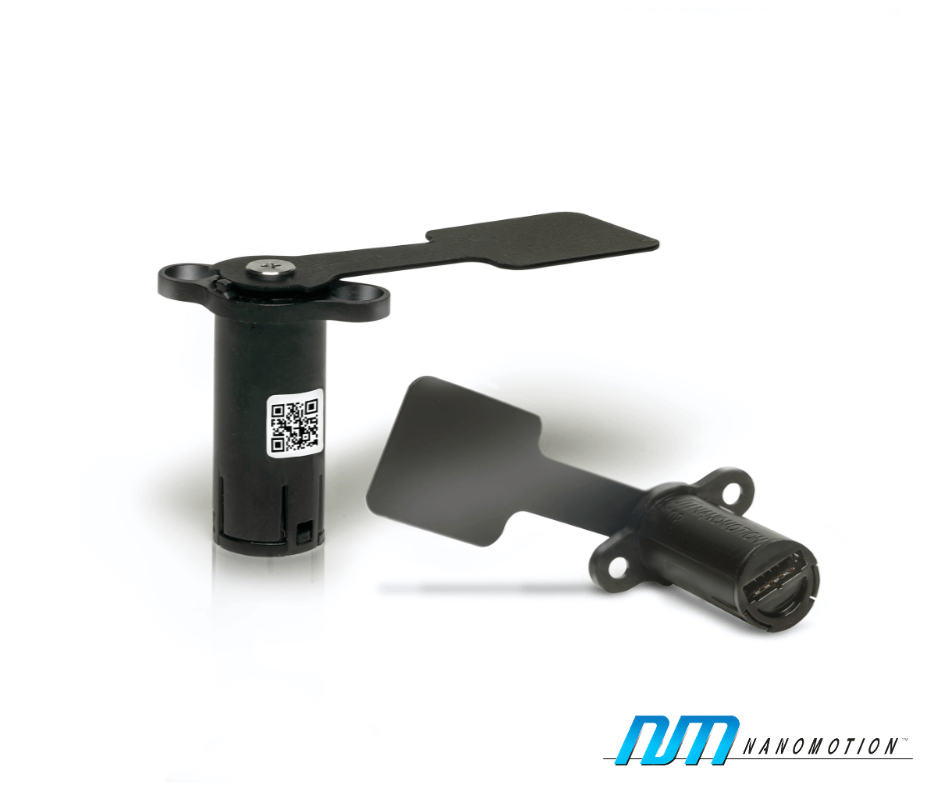

Product Focus

Flexure assembly facilitates the ability to move a sensor or mirror in relation to the grading to collect data of hundreds of wavelengths in a short time. This platform can provide scanning at 1kHz, to analyze gasses and materials for threat detection and survelillance.

Nanomotion’s TFM platform utilizes 3 piezo actuators, in a traditional expansion mode, rather than an ultrasonic mode. A flexure is used to multiply the travel in the vertical direction, with miniature position sensors embedded to close the loop, in a ~25mm diameter 3 axis assembly. 4µm of horizontal actuation translates into 16µm of vertical displacement.

Email Nanomotion for more information on products designed to facilitate hyperspectral imaging.